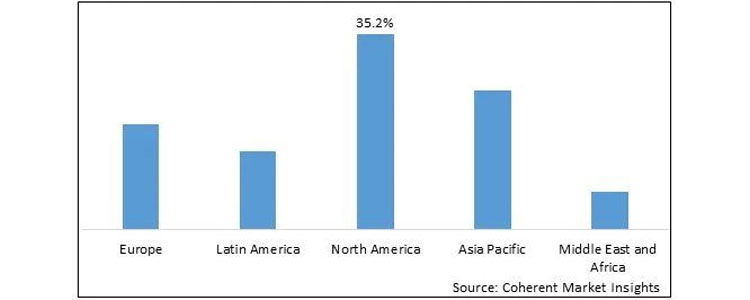

Regional Insights:

-North America, especially the U.S., holds a crucial position in the drone battery market.

-The North America market is expected to witness significant growth during the forecast period. This can be attributed to high adoption of advanced technologies and presence of key industry players, both of which help in creating ample growth opportunities.The U.S. will account for 95.6% of the North American drone battery market in 2023.

-Europe is also playing a significant role in the global drone battery market, showing significant growth at a compound annual growth rate (CAGR) from 2023 to 2030. The region exhibits favorable market expansion and investment climate.

In conclusion, the global drone battery market shows immense growth potential over the forecast period, with North America and Europe playing a key role. The market size and CAGR are expected to grow significantly, driven by factors such as technological advancements and presence of key players.

Drivers:

1. Increasing Demand for Drone Delivery and Mapping Services

Growing demand for drones in various industries such as agriculture, construction, and defense is driving the growth of the drone battery market. Drones are used for tasks such as surveillance, mapping, inspection, and delivery, which require reliable and long-lasting batteries. The growth of the commercial drone market is driving the growth of the drone battery market, driven by the growing demand for drone delivery and mapping services.

2. Faster Charging, Adaptability, and Performance

While there are many ways to improve lithium-ion drone batteries, the overall trend is toward improved safety, faster charging, better shape adaptability, and higher performance.

Commercial drones are revolutionizing old commercial and industrial systems, paving the way for smart operations to improve production. Commercial drones are used for much more than taking pictures or videos. Drone delivery is one of the most popular uses. As the technology develops and matures, the idea is expected to gain more traction.

Constraints:

Battery manufacturers face many difficulties, including complexity of setups and systems, long test cycles, and compliance with changing safety regulations. In addition, battery testing becomes difficult and lengthy due to the complexity of battery systems and the use of hazardous materials. Batteries can explode from high currents, toxic compounds and high voltages.

For example, most battery manufacturers perform life cycle testing, which can take six months or more. This takes a lot of time because each application requires individual testing.

Opportunity:

Lithium-ion batteries have advantages over other types of batteries (e.g. NiCd and lead acid). Lithium-ion batteries can be used in small sizes because of their light weight, and can then be used in RPAS (Remotely Piloted Aircraft Systems), which are compact, have no pilots and have to be as small as possible to have similar functionality as a true commercial airplane. However, these batteries are much more expensive than other batteries and have very high safety requirements, with a corresponding significant increase in manufacturing costs.

Post time: Dec-01-2023